M143 H0 S122 set temperature limit for heater 0 to 122C M305 P0 T50000 B2718 R4700 set thermistor + ADC parameters for heater 0 50K bed

M307 H0 B0 S0.66 F400 disable heater bed bang-bang mode set max PWM, up Hz, 120W peak with extruder heater Amps jumping around M558 P0 H5 F120 T6000 disable Z probe but set dive height, probe speed and travel speed M574 X1 Y1 Z2 S0 reversed X&Y axis May6 2020 X low end, Y low end, Z high end, S0 endstop triggered active low Vout M906 X450.00 Y450.00 Z450.00 E400.00 I0 Set motor currents (mA) and motor idle factor in per cent, Z&Y steppers not quiet at 475ma PSU19.4V M566 X900.00 Y900.00 Z900.00 E120.00 set maximum instantaneous speed changes (mm/min), speed threshold for executing next gcode move M350 X256 Y256 Z256 E256 I0 Configure micro stepping with no interpolation M569 P3 S1 E Physical drive 3 goes forwards M569 P2 S1 Z Physical drive 2 goes forwards M569 P1 S1 Y Physical drive 1 goes forwards M569 P0 S0 X Physical drive 0 goes backwards M587 S"xxxxx" P"xxxxxxxxxxxx" Configure access point. ****** X&Y axis swapped origin now front left The belts have glass cords and they establish the printer motion accuracy together with the steppers so no calibration is even possible aside from axis tramming. If your Z axis brake/clutch slips fix or increase the stepper idle current so the extruder linear rail does not fall on the print! I upgraded to a 24V power supply and in the config.g below I turn off the steppers when the print finishes. If you add a steel bracket and tie the Z stepper face to the aluminum base it improves dramatically. The stock Z axis on a Cetus shakes whenever the extruder accelerates. Motor acceleration settings are an accuracy vs vibration trade off and you just pick your poison. The upper bed temperature is limited to the 80s and after a long warm up using the stock Cetus power supply. M307 H0 B0 S0.45 F200 it heats to 55C at the same time as the nozzle get to 215C. My 200W 24V silicone bed heater needed a lower duty cycle and higher PWM frequency to not trip the 120W Cetus AC adapter’s internal short detection circuit. I find that with 0.1mm layers the washboard surface texture increases while it is very hard to see when printing with 0.15 and thicker layers. Any lower does not improve the print finish and higher adds an annoying minor washboard texture to the print surface. The extruder motor rotor is shorter and scaling the axis motor current you get a drive current of about 333ma.

The axis motor currents can be 450ma any lower does not improve the print finish and at 475ma they start making noise. Measuring thread geometry is a good extrusion test and it quickly reveals temperature, layer height, filament brand, colour etc. It’s like a micrometer in that it measures the clearance between the printed nut and bolt threads. The steps/mm is the iterative result is from a printing nuts and bolts sliced with prusa. I also have the warranty replacement MK3 style but the prints were just not as good so I eventually repaired the original. Extrusion steps for the original MK2 extruder mechanism that has a filament release lever is 1650 steps/mm. I choose 256 micro stepping without interpolation. Could be sensor jitter or CPU capture jitter, anyway it is very repeatable if done extremely slowly.Īfter a bunch of tuning I converged on a few variables that might be useful to others. The resulting trigger position is very repeatable and any faster results in the inductive trigger position having 2 or more nearby but stable values. The homing is done in 2 passes, fast and an extremely slow second pass (F0.1). The diodes are wired so they can only pull down the Duet input pin while the inductive sensor output signal swings from 0.6V to 24V. Looking at the numbers I believe the lower forward diode voltage drop meets the worst case Duet input voltage thresholds, regardless it works fine.

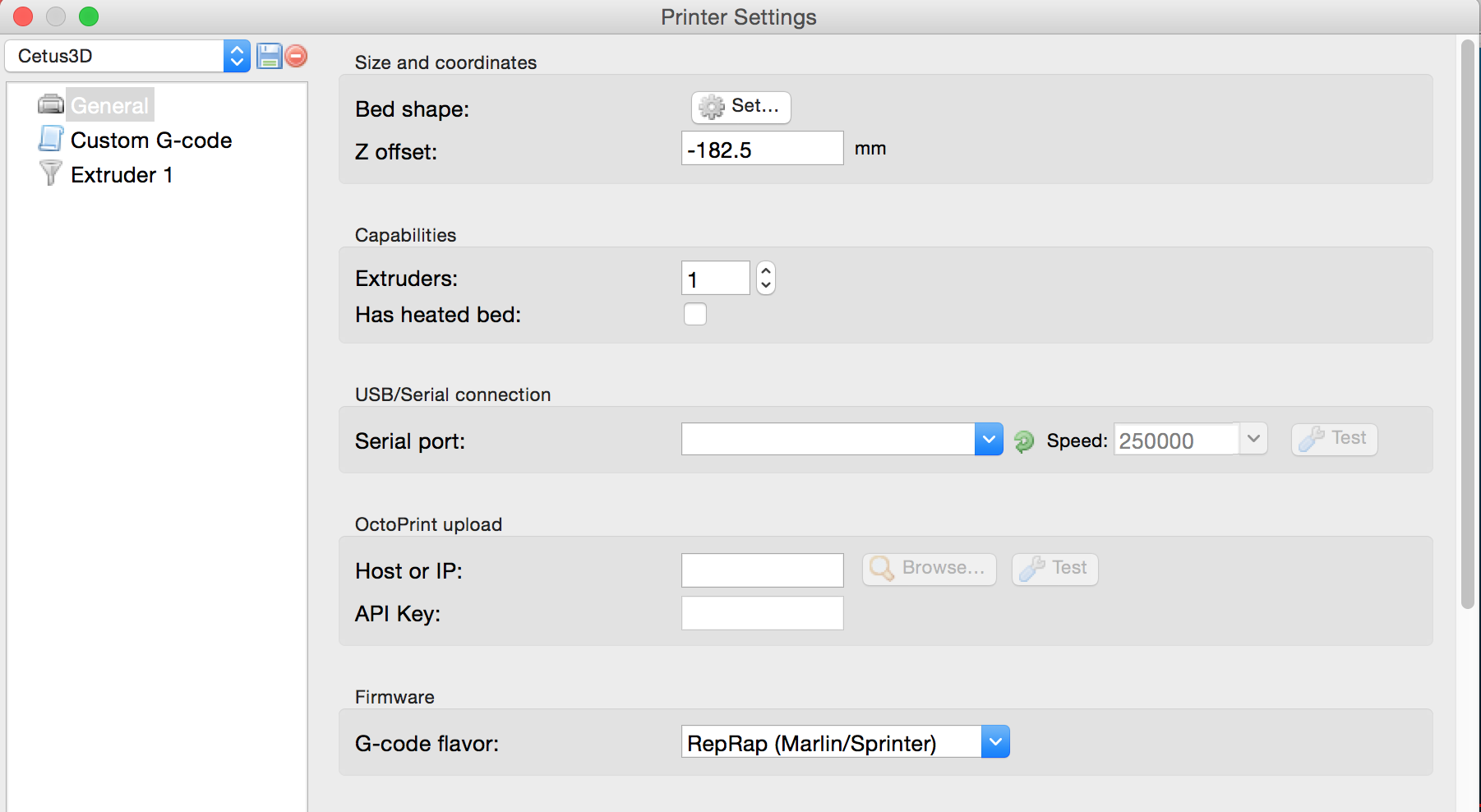

To interface the inductive sensors output to the Duet I used Schottky diodes. All three of my inductive sensors are stationery requiring Z be homed before Y, however, this keeps the accelerating mass down and the sensor wiring stationary. I choose inductive sensors for homing all the axes. I designed some parts for my Cetus Duet2 WIFI conversionĭon’t judge me but I started this about a year ago in the middle of some online configurator tool issues and had to modify the config files the hard way, much easier now.

0 kommentar(er)

0 kommentar(er)